Transporting an item can be effortless with the use of conveyor systems. They are common in industrial work which is operated in three ways – manually, motored, or by gravity. The equipment is made of durable pieces, such as belts, rollers, and wheels that will suit a variety of applications.

Choosing the right conveyor system is the first step to supporting better production. The good news is that you have clicked an article that will help you understand each type of conveyor and the important factors to consider before buying.

Things To Consider For Conveyor Systems

1. Load Capacity

Since the conveyor will carry materials, it matters to know its maximum load capacity. This depends on the unit’s length which is customized according to the user’s requirements. It can handle both light and heavy materials.

2. Speed

The rated speed varies for different types of conveyors. For instance, a belt conveyor is measured in ft/min while roller conveyors are based on the package unit.

3. Frame

Conveyors have different frame shape designs, like straight and curved. Each one plays a vital role in transporting goods.

4. Direction

A change of direction is necessary for carrying some materials. This is why conveyors are made of drives located at the end or center of the unit.

Choosing a Conveyor System

The kind of materials subject for transport plays a vital role in selecting the right conveyor unit. Consider their texture, size, and weight to easily determine which type of conveyor system best suits your needs.

Conveyor systems work in two ways. One is moving items from one point to another with many factors to keep in mind. A certain amount of material must be moved in real-time to avoid contamination. The second is a feeder system that is more sensitive to time at a continuous speed.

It also matters to pick the right size of conveyor that fits in your workspace. Also, maintain proper temperature in the facility to prevent potential risks and not harm the unit.

Buying a conveyor system can be complex if it is your first time. Contact an expert to discuss with you the various conveyors that will suit your workspace.

Common Types of Conveyor Systems

Conveyor systems really make industrial jobs a lot easier and quicker. Here is a list of conveyor units and their uses that you may consider investing in:

1. Belt Conveyor

This is a powered conveyor made of two pulleys, and a roller underneath to create an endless loop while transporting materials. It has a metal slider to prevent friction when moving light loads. A belt conveyor is built with durable materials, like metal, plastic, and rubber that can load heavy and bulk items safely. It can operate at various speeds, depending on what the task requires.

The system can function horizontally or in an incline position which proves its versatility for industrial jobs.

2. Roller Conveyor

This one works for baggage handling and other assembly line tasks. It operates manually or by gravity, depending on whether its position is either inclined or in floor space. The unit is not powered and is also used for loading docks.

3. Magnetic Conveyor

Moving magnets are part of this conveyor that helps to eliminate ferrous chips during operation. It performs in horizontal, vertical, or combined motions. It is not complex to use and is made for certain tasks.

4. Pneumatic Conveyor

The use of air pressure is crucial for some material handling jobs. A pneumatic conveyor is designed for mineral and food processing. There are various sizes available but choose the one that fits your loading requirements. Identify the particular materials it can handle before using the system for better safety.

5. Wheel Conveyor

A wheel conveyor is very common in moving packages. The number of wheels varies depending on the application, and so does the wheel spacing. It is powered manually or by gravity to deliver an excellent performance.

6. Vibrating Conveyor

If you are looking for a conveyor system that moves dry materials, this one is a good choice. The unit operates through rotary or linear pulsing, depending on the sort of materials to be transported. They also differ in design and sizes, whichever suits your specific needs.

7. Vertical Conveyor

This is a conveyor made for elevated industrial works. It can move items upwards and downwards with a certain speed and load height. Pick a vertical conveyor based on your load requirements and workspace layout.

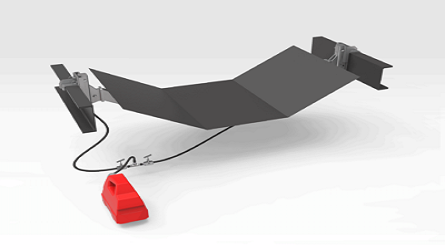

8. Screw Conveyor

This is common in wine facilities. It transports and mixes materials suitable for wine making with its spiral elements. It also applies to carrying wet materials toward other mechanical tools, like a press for wine production. Workers can take full advantage of its strong rotational force for a well-done job.

9. Overhead Conveyor

The word “overhead”, means that this conveyor can be mounted to perform material handling applications. Products such as garments that require to be hung and cool down may use overhead conveyors. Additional tools are necessary, like carriers and trolleys to use this equipment 100%.

Final Thoughts

To summarize, the conveyor systems come in various types for a particular use. Investing in some added tools, like conveyor belt lifters, can enhance the performance of the unit. Find a reliable individual to assist you in finding the most suitable tool for your needs.